Our 10 Ultimate DIY Window Installation Tips You Need To Know!

It’s finally time to install the off grid cabin’s vinyl windows and as always you’re getting the front row seat!

We’re going to share with you every tip we know for installing vinyl windows that won’t leak, will help reduce heating/cooling costs and last the life of your home.

If you’ve been following along with the build of our cabin then you’ve already seen us frame the rough openings for the windows and doors.

When framed properly, as we taught in our framing section here, the actual window and door installation is quick and easy.

In fact, we installed all nine vinyl windows plus the exterior front door in just one day.

We’ll cover the entry door installation tomorrow.

For the full detail behind why we choose vinyl windows for our off grid home be sure to check out our post called 11 Essential Factors When Choosing Your Off Grid Windows and Doors.

The Windows We Choose

As you may recall from our post Delivering 20K lbs Of Building Materials Off Grid we purchased all our building supplies from Home Depot including all nine windows, the front entry door and the two sliding pocket doors.

The windows we choose are made by JELD-WEN.

We choose to go with ENERGY STAR qualified low-E single-hung vinyl windows with fiberglass mesh screens. These are excellent windows for our environment here in Nova Scotia and stand up to the chilly winters and hot summer very well. They require little to no maintenance and will not swell or warp as some wooden windows do.

We loaded all our building materials, lumber, tools, gravel, windows and doors by hand onto a small folding utility trailer and towed it with an ATV down a trail we also blazed by hand!

Size and Cost of Our Windows

We have a total of nine windows.

The following sizes are all in inches.

1 Loft Window: 30X36 – $185.00

1 Kitchen Window: 30X36 – $185.00

1 Bathroom Window: 24X36 – $149.00

1 Master Bedroom Window: 30X36 – $185.00

5 Living room Windows: 2 front 30X48 – $209.00 (total $418.00) 2 side 36X48 – $219.00 (total $438) and 1 rear window 36X48 – $219.00.

Total Cost = $1779 (before tax)

Want a complete cost breakdown of our 24ft x 20ft off grid home including the building materials list?

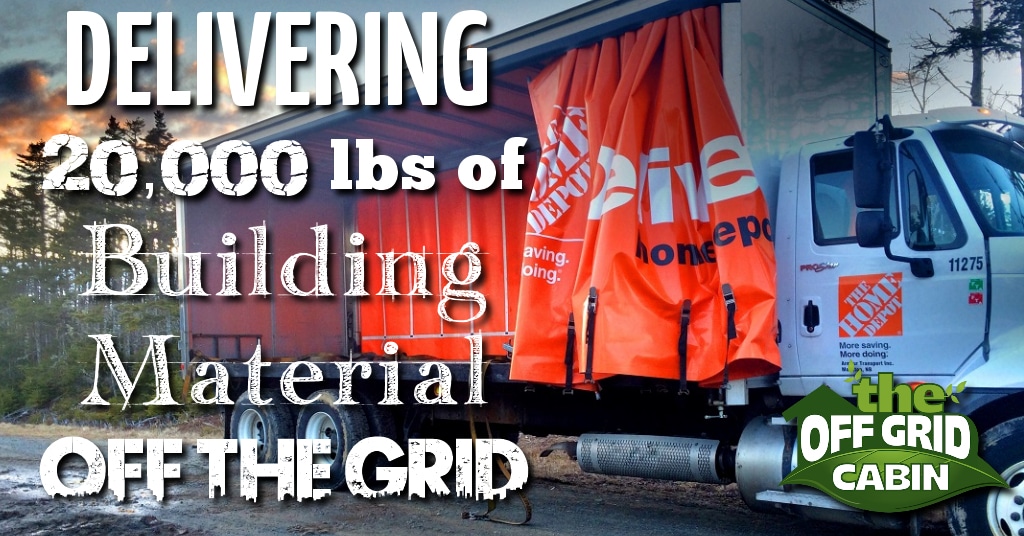

Show Me The Complete Package!Here is a quick review of three different methods for framing rough openings for windows.

You can see in the panoramic views below how we framed our windows using the extra cripple method.

CLICK TO VIEW A FULL SCREEN VERSION

You can see the entire three day framing process of the off grid cabin here.

Gather These Tools Before You Begin

To make the window installation process quick and easy gather up the following tools and supplies before you begin.

Please note: many of these links below are affiliate links, so when you purchase any of these items through the links on this page, we will receive a small commission that is used to help keep The Off Grid Cabin running. We’ve found that Amazon has excellent product descriptions, detailed personal reviews, and some of the lowest prices available.

These are all products that we either personally own, use or support and if you purchase items through these links, you have our sincere thanks!

- Level

- Pry bar

- Hammer

- Utility knife

- Wood shims

- Tape measure

- Expanding foam

- Cordless drill & drill bits

- Caulking & caulking gun

- Vinyl drip cap (if required)

- 1 ¾” Galvanized roofing nails

- Spray adhesive for additional flashing or building wrap

A quick word on nails: Choose nails designed stand up to the weather in your area when purchasing nails for your vinyl window installation. Most outdoor nails are designed for this type of work, so stick to the nails that have been proven to withstand corrosion. Aluminum and galvanized nails both work well. Which is what we used. Stay away from stainless steel for this application as it can chip when hammered and eventually rust and stain the window and siding.

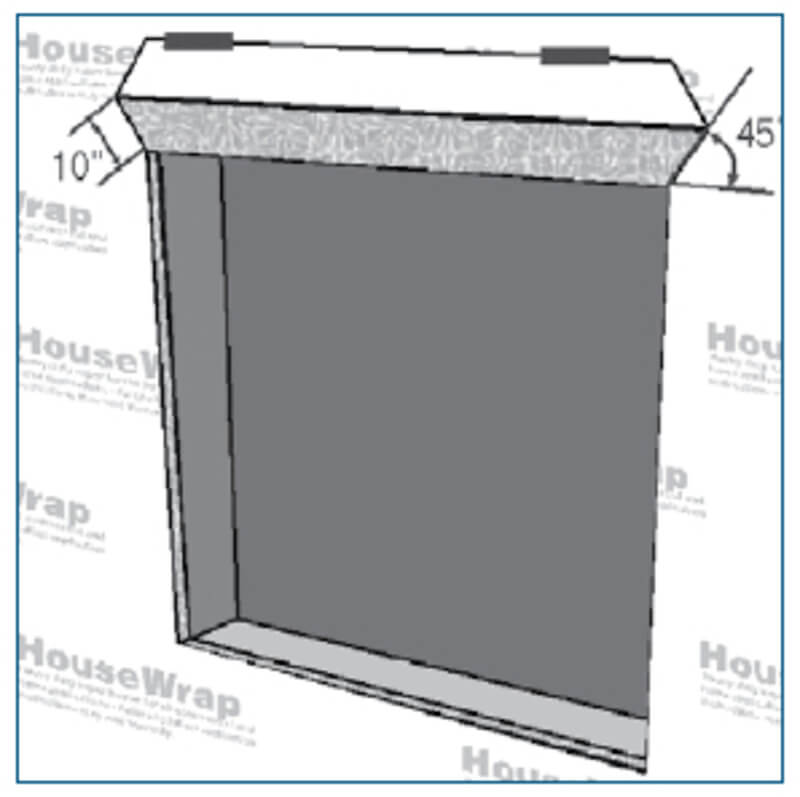

The installation procedure for each window is exactly the same. We already have the Tyvec on, cut to 45 degrees at each corner and folded in so that it covers all four edges of the roughed in window frame which helps further protect the sill from moisture. More details on this below.

Have the appropriate window(s) placed near the rough opening and test the dry fit to ensure the rough opening is suitable. For window opening that are higher up it may be easier to pass the window out through the opening instead of trying to climb a ladder while holding the window.

Step-By-Step Window Installation

Step 1: Inspect the window before you install it. Check for cracks, splits or missing sections in the nailing fin longer than 6” and make sure there are no holes or cracks within ½” of the window frame.

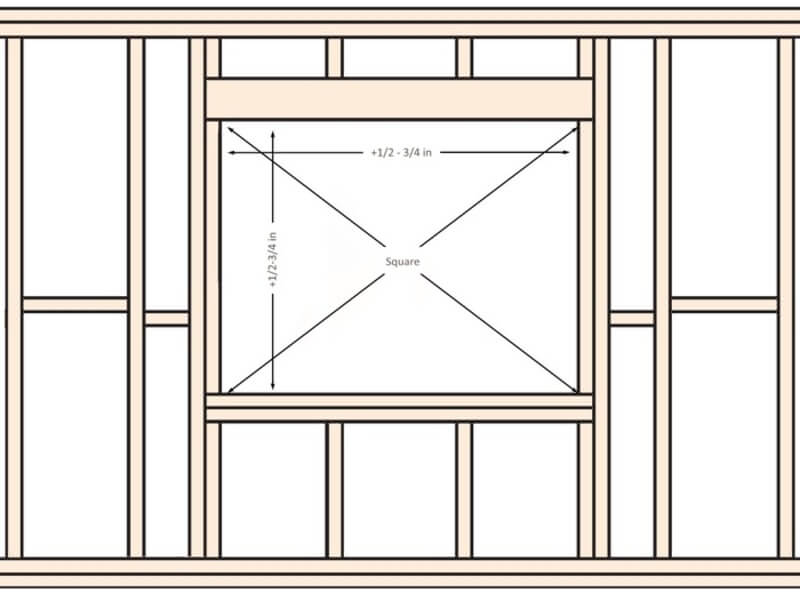

Step 2: Ensure the window opening is square by measuring from corner to corner. There should be no more than ¼” difference for windows larger than 20 sqft and no more than 1/8” for windows smaller than 20 sqft.

For vinyl windows like ours that have a nailing fin make sure the width and height of the rough opening is approximately ½” larger than the window. Also, make sure the sill opening is level and not crowned or sagged. It is advisable to slightly slope the sill from the inside out.

The inside of the sill should be approximately 3/8” higher than the outside or approximately a five degree slope.

Here’s a simple three step method for shimming the sill to produce a five degree slope if you’ve already framed your rough openings or your putting in replacement windows.

1 – Measure and mark the 5 degree slope you wish to make.

2 – Use a reciprocating saw to cut the studs along the 5 degree mark you made.

3 – Insert a wooden shim to secure the sill at a 5 degree angle.

Step 3: Prepare the sill by folding in the Tyvec to protect the inside edges of the roughed in window frame.

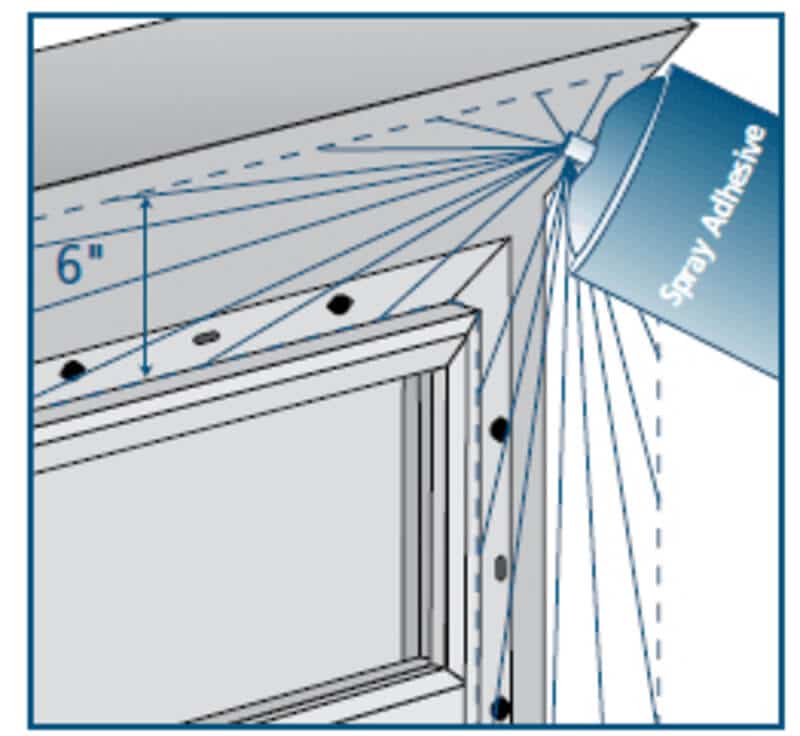

You can also shiplap additional building wrap and use a spray adhesive to secure it. We simply tucked all four corners of the Building wrap back inside the rough opening. We’ll be installing vinyl drip caps on all the windows when we put the vinyl siding on in a future post.

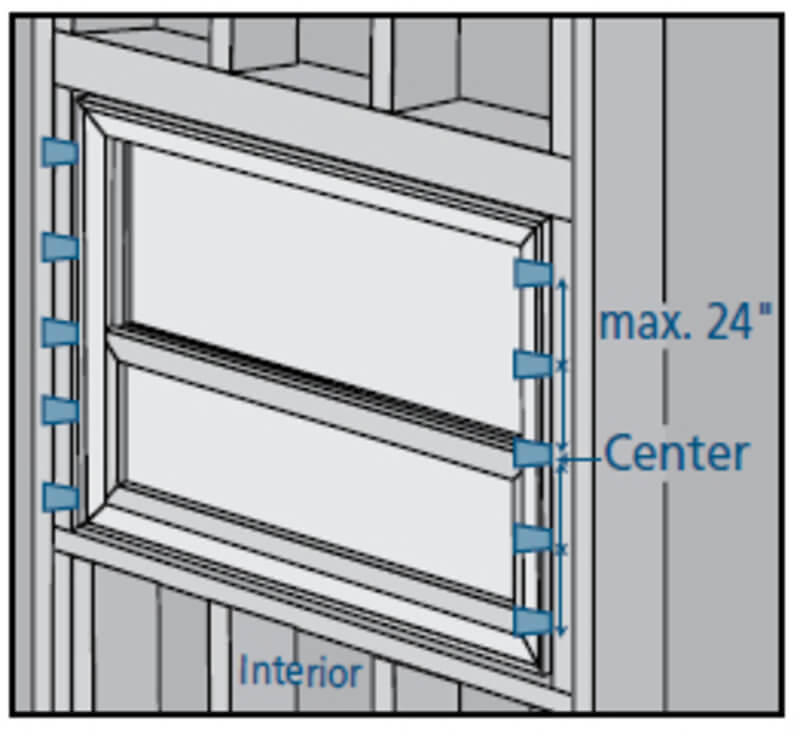

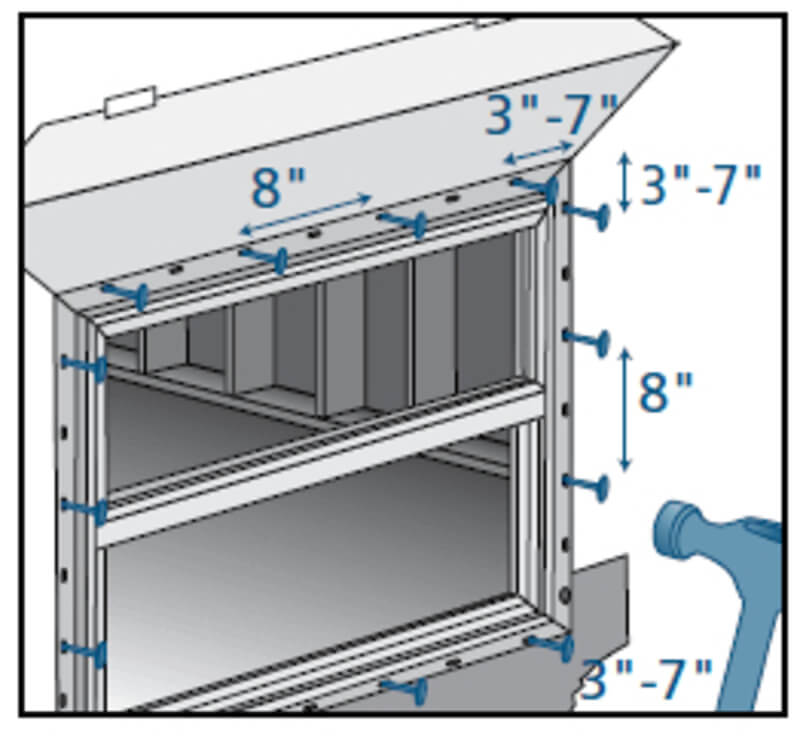

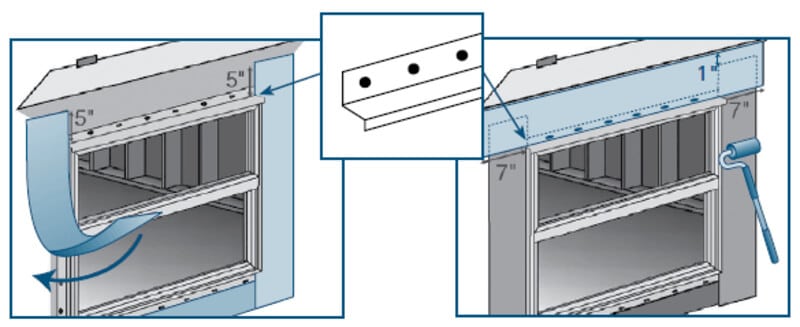

Step 4: Place the window in the rough opening and temporarily fasten the window with a nail through a nailing fin hole between 3” – 7” from the top corner. Insert the shims along the sides, between the vinyl window frame and the studs. Align the shims with the predrilled holes or 3” – 6” from the corners and at 8” intervals (max 24”).

Inspect the window for square, level and plumb and adjust with the shims as needed.

Fasten the window through the side jambs predrilled holes and shims.

Step 5: Finish nailing the exterior nailing fin.

Step 6: To further weatherproof the window installation in extreme weather condition areas, cut three pieces of 6” self-adhesive flashing. One header piece 14” longer than the header. Two side pieces 12” longer than the sides. Spray adhesive/primer to the nailing fin, sheathing and building wrap at the sides and head of the window.

Affix the additional two side pieces starting 5” above the header. Next, install the drip cap, which should extend ½” on each side. Lastly install the header piece and roll everything flat with a j-roller.

Note: You’ll see us install the vinyl window flashing when we install the siding.

Finished with the window installation inside.

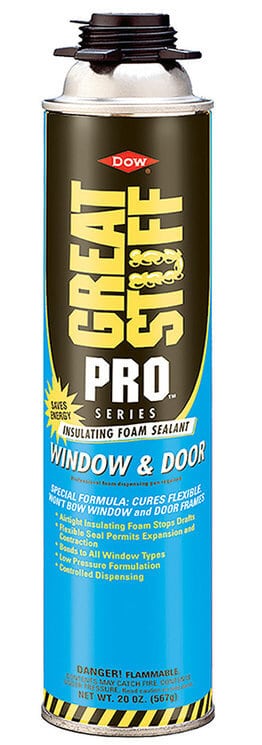

Step 7: From the inside, fill in any air gaps between the vinyl window frame and the studs, the bottom sill and the top header with the appropriate foam sealer.

TIP: We used Great Stuff Pro Windows & Doors which is specifically designed for this application. This particular sealing foam won’t expand, and bow/warp the window frame like regular expanding foam will.

Each window took us approximately 30 minutes to install, shim and finish nailing down.

Finished with the window installation outside.

Note: If you’re installing vinyl replacement windows the procedure will be exactly the same once the old window(s) is removed.

Window Installation Conclusion

There’s a lot that goes into selecting the appropriate windows for your off grid build but the installation process itself is quite a simple one.

The key takeaway here is that the rough opening built during the framing phase is a crucial step to ensure a smooth installation.

Know the exact size of each window before you even begin framing.

While you can make changes later, it’s far easier to frame it right the first time.

Do it right the first time!

Be sure to frame your openings larger by the amounts we specified above and remember to follow the manufacturer’s recommendations. We’re off grid building enthusiasts, not building experts remember so always follow the manufacturer’s guidelines.

In the next post we’ll show you the front door installation with the exact steps to take to ensure you have a perfectly weatherproof, smooth operating front entry door.

Ready To Check Out The Next Step Of The Build?

Your Turn...

So, are you ready to install windows like a pro on your own?

Let us know in the comment section at the bottom if you think you can do it!

If you’re not already following the build be sure to visit our How We Build The Cabin section so you can check out the build right from the start!

For all our Pinterest pinners out there here’s a special pin for you!

I have to agree with the nailer. Makes things much easier much quicker. Thanks for this. A huge help in building my retirement dream.